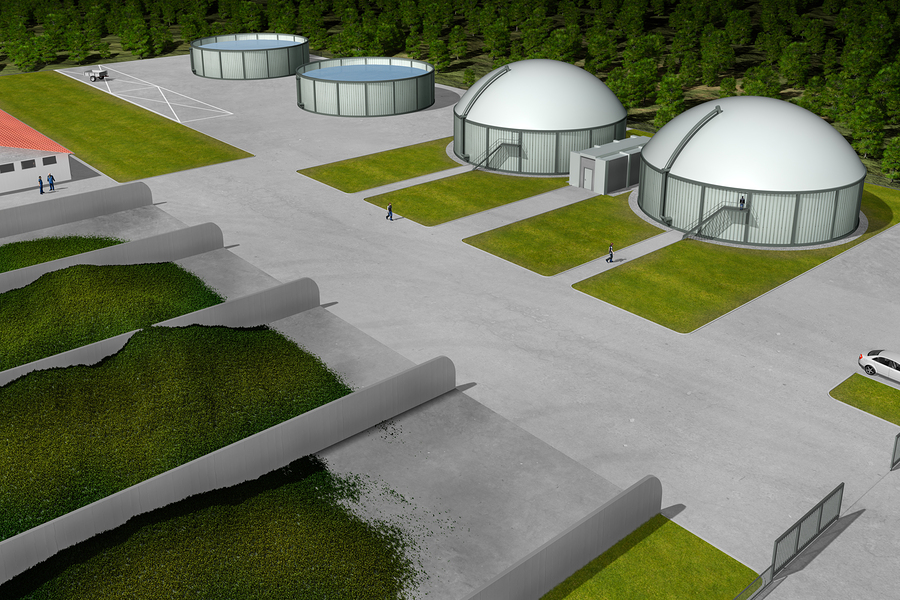

Biogas Plant, Banjul, Westafrica

SPBS designed Blast-Safe ™ security rooms with 25% thinner walls than usual (C45/55). Installations for employees got additional protection against attacks with guns & rifles. The material is also suitable for areas with high risk of earthquakes and stormy areas. The material is also F90 fireproof.

THE CHALLENGE

Engineers face increasing pressure to manage and utilize waste (whether of animal, human or municipal origin) in a sustainable way. We suggest that a solution to the problem of organic waste in rural communities lies in their being able to convert it to biogas technology. This would offer smallholders and farmers a long-term, cheap and sustainable energy source that is independent of the national electricity grid. However, although the technology involved in making biogas from waste has already been fully developed, there are obstacles impeding its adoption. First, there is a general ignorance about this source of energy among the very people who can most benefit from using it. Second, at present, Africa has no regulatory framework to support the installation of biodigesters.

THE STRATEGY

The research focused on the current gap between knowledge and need. The two objectives were raising general awareness of the many and varied benefits that biodigestion can offer, especially to rural communities, and demonstrating how it works. Using science events as a platform, the team introduced the concept of biodigestion, its functioning and uses, to their audiences, and then invited informal responses, which were recorded. The second stage, the case study, entailed the setting up of a small-scale (10 m3) household biodigester. It was put into operation, using fresh cow dung as the feed. Members of the community were invited to watch every step of the process and afterwards were asked to participate in a more formal survey, which sought their opinions on whether biodigestion offers a power source the individual farmer could (and would) use.

BIOGAS PLANT

BIOGAS PLANT SKETCH

Client’s Testimonial

“An important aspect of the project was that when SPBS built this structure for us, we had to deactivate a very important part of our production line in order to have them perform the work. We determined that we only had a three month window during our slow season; we gave SPBS the tight deadline to work with and they actually completed the 60,000 sq ft area incl. the offices 10 days early. They did everything they said they were going to do and came through ahead of time and on budget…”

Benjamin Tickle, Project Manager

WestAfrica BioComp Inc